Water Adjustment

- Introduction

- Parts and tools

- STEP 1: Choose a flavour profile

- STEP 2: Starting water composition

- STEP 3: Calculate salt additions

- STEP 4: Measure salt additions

- STEP 5: Brew day

- Pictures / Videos

Introduction

Proper control of water is an important step to brewing any style of beer consistently and successfully. It's yet another aspect in brewing that can take a beer from 'good' to 'great'. It allows starches to be efficiently converted to sugars, promotes clarity and long term stability, and plays an equally important role in creating the flavour profiles we all know and love.

There are no tricks or shortcuts to this no matter what some brewers or product manufacturers may lead you to believe. Without proper control of water, many brewers will find out through trial and error that they are only able to brew certain styles of beer to their liking, if any at all.

Many years ago, before water and mash chemistry were well understood, certain regions of the world were only able to brew and market certain beer styles successfully. This was due to the specific water composition of the region and how the naturally occurring minerals affected the flavour and reacted with the grain bill to alter the mash pH. Trying to brew different styles still made "beer" of course, but the product simply wasn't as good and the beer did not sell well. Various regions were forced to stick to styles that worked best for them. Many areas around the world became known for the styles they were able to successfully produce. For example, Czech lagers brewed with the soft (low mineral) water of Czechoslovakia, to English Burton-on-Trent ales and German Dortmund lagers brewed with hard (high mineral) water.

Today, a brewer armed with the knowledge of how to adjust their water can successfully brew any style of beer imaginable, anywhere in the world. This guide will show you how, taking you through step by step, without getting bogged down in complex math or chemical formulas. (We hate chemistry!)

If you truly want to 'geek out' on the science and chemistry behind water and brewing, take a look at the book Water: A Comprehensive Guide for Brewers. (Frankly, we'd rather just brew).

We promise that this guide will be free from graphs and chemical formulas! (No offence to Palmer & Kaminski)

We promise that this guide will be free from graphs and chemical formulas! (No offence to Palmer & Kaminski)

Parts and tools

Purchasing through our affiliate links helps support our site at no extra cost to you. We thank you!

STEP 1: Choose a flavour profile

Different beer styles will call for different levels of minerals to achieve the flavour profile we are targeting. By adjusting the amounts of specific minerals found in your brewing water, beer can be made to taste fuller bodied, sweeter, drier, more bitter, or even sour. The levels, or concentration, are typically expressed in parts per million (ppm).

The following minerals found naturally in water are the ones we adjust in brewing:

- Calcium (Ca): Essentially flavour neutral. Promotes clarity and flavour stability of the final beer. Affects enzymatic activity in the mash, protein coagulation during the boil and benefits yeast health. Typical brewing range is 50-150 ppm.

- Magnesium (Mg): Adds a sour, astringent flavour. An important yeast nutrient, required at a level of least 5 ppm. Levels above 125 ppm have a laxative effect (fun times).Typical brewing range is 5-40 ppm.

- Sodium (Na): Rounds out flavours and accentuates sweetness. Lower concentration tends to produce a cleaner flavour. May taste salty above 150 ppm and harsh / sour above 250 ppm. Typical brewing range is 0-50 ppm, but some special styles (like Gose) may go as high as 250 ppm.

- Chloride (Cl): Accentuates flavour by making a beer fuller bodied, rounder, and to appear sweeter. May taste salty above 250 ppm and will affect yeast health above 300 ppm. Typical brewing range is 0-250 ppm.

- Sulfate (SO4): Accentuates hop bitterness / dryness / crispness. May become astringent above 400 ppm. Typical brewing range is 50-350 ppm.

Adding these minerals to our brewing water is unfortunately not as simple as buying a bottle of each and adding a pinch of this and a dash of that. Through the wonders of nature (we promised no chemistry here!) many of these minerals cannot safely exist on their own, in a stable form. Pure sodium (Na), for example, is a toxic metal that explodes if it comes in contact with water which would make for a very bad brew day. But combine sodium (Na) with chloride (Cl) and we create a stable salt, in this case regular table salt (NaCl). So when we add minerals to our water, we're usually forced to do so two at a time using readily available and stable salts. Adding salts also happens to affect pH, but more on that later.

The salts we use to adjust the mineral content of our water are as follows:

- Gypsum / Calcium sulfate (CaSO4): Adds Ca and SO4, lowers pH.

- Calcium chloride (CaCl2): Adds Ca and Cl, lowers pH.

- Pure epsom salt / magnesium sulfate (MgSO4), unscented: Adds Mg and SO4, lowers pH (very slightly).

- Chalk / Calcium carbonate (CaCO3): Adds Ca, raises pH.

- Baking soda (NaHCO3): Adds Na, raises pH.

- Non-iodized salt (NaCl), also known as pickling salt / kosher salt / cheese salt: Adds Na and Cl, raises pH.

Out of these six salts, the first three are the ones we use the most. We will sometimes use chalk with dark beers where we want to increase Ca without affecting other minerals. We have yet to use baking soda or non-iodized salt after many years of brewing.

We keep our brewing salts in sealed spice jars that sit on a wall mounted stainless steel spice rack. Labels are added using an inexpensive Dymo LetraTag Plus personal label maker.

The various brewing salts we use for adjusting water

The various brewing salts we use for adjusting water

Before you can pick a flavour profile, you have to have a beer recipe or style in mind. For this guide, let's use the Blonde Ale we feature in our Brew Day Step by Step guide as the target style and show how to adjust water to suite this beer.

Our Blonde Ale is a lighter bodied, balanced beer. It is neither malty nor hoppy so we won't be looking to accentuate any specific flavours.

With our Blonde Ale we are interested in keeping calcium (Ca) and magnesium (Mg) fairly low and hitting the minimums (the values of which are a highly debated topic) in order to keep the yeast and enzyme reactions happy. Both chloride (Cl) and sulfate (SO4) we want to keep reasonably low and close to balanced. As mentioned above, high sulfate may enhance bitterness / dryness while high chloride may enhance flavour or maltiness. We're not looking for either of those attributes here given that the beer is to be lighter bodied and quaffable. For most beers we want to keep sodium (Na) low as it tends to produce a cleaner flavour and that's certainly the target for this beer style.

With these in mind, for balanced beer like our Blonde Ale, we find that the following targets work well:

Blonde Ale water targets: Ca=50 ppm, Mg=10 ppm, Na=16 ppm, Cl=70 ppm, SO4=70 ppm

Want to brew something different? Below is a list of the water profiles we use most often:

-

Balanced

Profile: Ca=50, Mg=10, Na=16, Cl=70, SO4=70

Description: Hit minimums on Ca and Mg, keep the Cl:SO4 ratio low and equal. Does not favour flavour / maltiness or bitterness / dryness. For balanced beers.

Recipes: Blonde Ale / Premium Lager, Cream Ale / Standard Lager, Schwarzbier, English Pub Ale, Irish Red Ale, Dry Irish Stout, Russian Imperial Stout, Witbier, Weizen / Weissbier, Weizenbock, Dusseldorf Altbier, Munich Helles, Kolsch, Maibock / Helles Bock, Belgian Dubbel, Belgian Tripel, Belgian Dark Strong Ale (Quadrupel), Belgian Super Saison, Belgian IPA, White IPA -

Hoppy

Profile: Ca=110, Mg=18, Na=16, Cl=50, SO4=275

Description: High SO4 with restrained Cl which helps accentuate hop bitterness / dryness. For hoppy American styles.

Recipes: Electric Pale Ale, Electric Pale Ale (Sessionable), Electric Hop Stand Pale Ale, American Amber Ale, Janet's Brown Ale, Electric IPA, Green Flash West Coast IPA, Sierra Nevada Torpedo Extra IPA, Sierra Nevada Ruthless Rye, Bell's Two Hearted Ale, New Zealand IPA, Russian River Pliny the Elder (double IPA), Russian River Pliny the Younger (triple IPA), Stone 'Enjoy By' (double IPA), Bell's Hopslam (double IPA), Firestone Walker Double Jack (double IPA), Kern River Citra Double IPA, American Barleywine, Firestone Walker Wookey Jack Black Rye IPA, English IPA, American Red IPA -

Hoppy lite

Profile: Ca=110, Mg=18, Na=16, Cl=50, SO4=100

Description: Similar to the 'Hoppy' profile but with less sulfate in order to go easy on accentuating bitterness / dryness. Used in some English styles.

Recipes: Fuller's ESB, Fuller's London Pride, English Mild, Timothy Taylor's Landlord -

Hoppy New England

Profile: Ca=100, Mg=18, Na=16, Cl=200, SO4=100

Description: Increased Cl with restrained SO4 which helps accentuate flavour over bitterness / dryness. The hop bitterness is smoother, less sharp, less dry than our 'Hoppy' profile. Helps support a silky smooth and rich mouthfeel. For hoppy New England style ales.

Recipes: Electric Hop Candy (New England IPA), Electric Hop Candy Jr. (New England Pale Ale), Electric Creamsicle (New England Pale Ale) -

Soft

Profile: Ca=21, Mg=5, Na=18, Cl=16, SO4=21

Description: Just enough to acidify the mash while keeping the water soft.

Recipes: Czech Premium Pale Lager -

Pilsner

Profile: Ca=59, Mg=8, Na=16, Cl=63, SO4=93

Description: Hit close to minimums on Ca and Mg, the Cl:SO4 ratio favours SO4 which enhances hop bitterness but not as much as an aggressively hopped American style.

Recipes: German Pilsner -

California Common

Profile: Ca=50, Mg=10, Na=16, Cl=66, SO4=77

Description: Hit minimums on Ca and Mg, keep the Cl:SO4 ratio low and close to equal with slightly accentuated SO4.

Recipes: California Common -

Deschutes Black Butte Porter

Profile: Ca=129, Mg=10, Na=16, Cl=89, SO4=136

Description: Close to our 'Hoppy lite' profile but with elevated Cl for fuller body/mouthfeel. The numbers come from the Deschutes brewer Jimmy Seifrits.

Recipes: Deschutes Black Butte Porter

Our Magnesium targets tend to be on the low side as it occurs naturally in grain, so the actual amounts will always be higher than what you target.

Take a look at our recipes for more examples as we always include target water profiles with a short explanation.

Keep in mind that these numbers are not absolutes. Don't get hung up on precision or be concerned if you are not able to exactly hit our recommended targets. A 10% change (or possibly more) in any number is probably not going to be noticed in the finished product. Water can be adjusted to suit a particular brewer's tastes or needs just like any other brewing ingredient so feel free to experiment as well. How salts are used and adjusted in brewing is also constantly evolving. For example, it was common practice in American IPAs to keep the sulfate (SO4) level considerably high relative to chloride (Cl) in order to enhance the bitterness / dryness of the hops as is done in our 'Hoppy' profile. When the 'New England' style of IPA emerged the opposite was done to promote a smoother, less sharp, less dry bitterness.

Shouldn't I try and target certain historical profiles from famous brewing cities?

We don't recommend this approach. Some will tell you that it's best to adjust your water to match that of a classic brewing city or region. For example, trying to match the extremely hard (full of minerals) water found at Burton on Trent to brew an English beer. We find that approach backwards as it doesn't account for what the historic brewers may have done to the water to make it suitable for brewing their specific styles of beer (such as using slaked lime or boiling to reduce hardness). Water is only one ingredient, it doesn't tell the whole story. It needs to be taken in context with everything else that goes into making the beer. We recommend building your profiles based on the flavour outcome that is desired, not because historical brewers may have been forced to use specific water compositions.

STEP 2: Starting water composition

To be able to adjust our starting water to our target numbers, we need to know how much of these five minerals that we care about in brewing (Ca, Mg, Na, Cl, and SO4) exist in the water naturally. Our starting water levels have to be equal to or lower than our targets as you can always increase minerals by adding salts but cannot easily take them away. Other than pure reverse osmosis (RO) or distilled water, most water will have mineral levels higher than zero.

We use our city's water for brewing as it is very soft (low in minerals). If your city water is soft and tastes fine then using cold tap water is perfectly adequate and is definitely the easiest solution for most people. For now, assume you will be using your tap water. We'll confirm in this step if your water will work for the flavour profile you picked previously.

Most municipalities publish their numbers online or can provide them over the phone. Our city (Ottawa, Ontario) publishes a yearly report that contains all of the information we need (see our city's 2015 water report, excerpt below). Water reports tend to focus on the quality of drinking water so you'll need to wade through lots of information that isn't overly useful to brewers.

Our City of Ottawa 2015 Drinking Water Quality Report, important numbers highlighted

Our City of Ottawa 2015 Drinking Water Quality Report, important numbers highlighted

Water reports will express levels as either ppm or mg/L (they are the same thing).

Extracting the five important minerals (highlighted above), our city water numbers are:

Ottawa water: Ca=8.5 ppm, Mg=2.1 ppm, Na=16.3 ppm, Cl=5.3 ppm, SO4=26.7 ppm

As a reminder, our Blonde Ale targets are:

Blonde Ale water targets: Ca=50 ppm, Mg=10 ppm, Na=16 ppm, Cl=70 ppm, SO4=70 ppm

Comparing the two, we see that our city water is below our targets for all minerals so brewing with our city water should not be a problem. Remember that you can always add minerals in the form of brewing salts but cannot easily take them away.

Keep in mind too that mineral levels can vary throughout the year, more so in some locations than others. Our city's published numbers are averages taken over the entire year. Given that these averages are very low they likely do not vary much throughout the year, so we use them 'as is' all year. Over the last 5 years our city's averages have not varied more than a point or two. If your numbers are considerably higher than ours, you may want to ask your municipality how the levels tend to vary over the year.

My municipality can't provide me my water mineral numbers / I'm on a well

If the water mineral numbers are not readily available to you (such as when the water is sourced from a private well), Ward Laboratories offers their W-5A Brewer's Water Test Kit. You send them a sample, they analyze, and then email you the results. Prefer to do it yourself? Both Industrial Test Systems and Lamotte make test kits suitable for brewing. Useful if you wish to perform multiple tests or share the cost with your brew club.

My water report has sulfate as SO4-S instead of SO4. Is that the same thing?

Nope. You probably received a water report from Ward Labs who reports sulfate as SO4-S instead of of SO4. To convert to SO4 you need to multiply by 3. For example, if your water report indicates that you have 6 ppm of SO4-S, you have 18 ppm of SO4.

Some of my water mineral numbers are already higher than the targets!

If some of your mineral levels are higher than the targets, blend your water with mineral free reverse osmosis (RO) or distilled water until all of the levels are at least equal to or below the targets. For example, blending with equal amount of RO water would reduce all mineral levels to half the original values. If your water is very hard (high in mineral content) as is often the case with well water, you may find it easier to start with 100% RO or distilled water and "build up" the water using salts to hit the appropriate targets. When starting with RO or distilled water assume all of the starting numbers are zero.

What about all the other minerals / compounds / contaminants in my water report?

The five minerals that create the flavour profile we care about in brewing are Ca, Mg, Na, Cl, and SO4. Most other minerals and compounds and most definitely all contaminants should be close to zero if the water is to be used for brewing (let alone drinking).

The following substances should be as close to zero as possible in water used for brewing: Aluminum, arsenic, barium, bromate / bromide, cadmium, chlorine / chloramine (more on this in a later section), chromium, coliform bacteria, copper, cyanide, fluoride, total Haloacetic Acids (HAA5), iron, lead, manganese, mercury, phosphate, tetrochloroethylene (PCE), total trihalomethanes (TTHM), and trichloroethylene (TCE). The good news is that if your brewing water comes from the tap you generally do not need to worry about these levels as standards such as the US Safe Drinking Water Act and the European Drinking Water Directive legally require that these levels be kept close to zero.

The substances for which slightly higher levels are acceptable for brewing include: nitrate (<44 ppm), nitrite (<3 ppm), potassium (<10 ppm), and silica (<25 ppm). Most municipalities will, however, attempt to keep even these substances close to zero (a good thing).

For more information see chapter 3 of the book Water: A Comprehensive Guide for Brewers where each of the substances is explained in detail.

Can I use water from a water softener for brewing?

Maybe. Do not confuse soft water with water that's been passed through a water softener. They are not the same thing. Soft water is simply a term to describe water that is low in minerals. A salt-based ion exchange water softener on the other hand replaces minerals like calcium and magnesium that we want in our beer (to varying degrees) with either sodium or potassium. We want to limit both in our beer as lower concentrations tend to produce a cleaner flavour.

Potassium can taste salty at levels higher than 500 ppm and malt naturally already has high levels. Sodium at 150-200 ppm can start to taste salty, and above 250 ppm may taste hash and sour. Sodium combined with a high concentration of sulfate can result in an unpleasant metallic/bitter aftertaste.

Because of this we do not recommend using water that's been through a water softener to brew beer, especially if your untreated water is very hard. The harder the water, the more sodium or potassium that is required to treat the water such that more ends up in your beer. If you choose to use water that's been passed through a water softener, we recommend having it analyzed so that the sodium or potassium levels can be determined. This should be done every time the water softener is adjusted.

For more information on water softeners and the effects of sodium or potassium in beer, see the book Water: A Comprehensive Guide for Brewers.

Can I use bottled water / spring water for brewing?

Yes. Any water that is suitable for drinking can be used for brewing. However, spring water may have mineral levels that are too high to use depending on the flavour profile you are targeting. Check the label for a breakdown of the five minerals we care about (Ca, Mg, Na, Cl, and SO4) or contact the bottling company for details, and then compare with the flavour profile you are targeting. Keep in mind that using spring water will not automatically make your beer better. There is nothing special about spring water regardless of what some of the 'rocky mountain' macro brewers want you to believe.

Can I use reverse osmosis (RO) / distilled water for brewing?

Yes. When starting with RO or distilled water assume all of the starting mineral numbers are zero. Many brewers who only have high mineral content water available to them will resort to using RO or distilled water and "build up" to hit the appropriate mineral targets. If using a reverse osmosis system to create your own RO water make sure to follow the manufacturer's recommendations for changing the filter membranes as over time they become less effective. A total dissolved solids (TDS) meter is a handy way to understand how well an RO system is working as it (mostly) measures the amount of minerals in the water. Over time the TDS level will start to climb indicating that it's time to change the membranes.

Is it ok to use hot tap water for brewing?

Maybe. Some brewers choose to brew with hot tap water to reduce the heating time required. While an on-demand water heater or a newer hot water tank may be fine, older tanks that have not been properly maintained may introduce a 'minerally' taste to the water due to corrosion of galvanized plumbing which can accumulate in the hot water tank. In some cases there may also be higher levels of lead in the water too. We recommend that you follow the advice of the EPA who suggest that hot tap water not be used for cooking or drinking - brewing is both! If you use tap water to brew, it's best to use cold tap water that comes straight from the water supply.

STEP 3: Calculate salt additions

Before we can calculate the amount of salts we need to add to hit our mineral targets, we need to know how much strike and sparge water we will be using.

Our Blonde Ale is brewed with 18 pounds of grain, a mash thickness of 1.5 quarts per pound, a pre-boil volume of 14.9 gallons, and a standard grain absorption rate of 12%, resulting in 7.5 gallons of strike water and 9.6 gallons of sparge water. Below is a summary of the calculations from our Brew Day Step by Step guide:

Strike water = (Mash Thickness * Pounds of Grain / 4) + dead space under false bottom + liquid in hoses = (1.5 * 18 / 4) + 0.22 + 0.5 = 7.5 gallons

Sparge water = Pre-boil kettle volume + Liquid lost to grain absorption - Strike water = 14.9 + (18 * 0.12) - 7.5 = 9.6 gallons

For a more detailed explanation of strike and sparge water, see our Brew Day Step by Step guide.

We now have all the numbers we need to calculate the salt amounts required to hit our mineral targets. There are many tools available to perform these calculations. We like to use the free spreadsheet EZWaterCalculator as it's one of the most intuitive and easy to use tools we have come across. Downloadable as well so you have something you'll be able to use for life.

Download EZWaterCalculator and enter your values into the Step 1 areas highlighted in yellow below. This is your starting water profile information (Ca, Mg, Na, Cl, and SO4) along with your strike / sparge water amounts (the 'Mash Water' field is your strike water). If blending with RO or distilled water, enter the percentage used and the spreadsheet will automatically adjust your resulting water profile numbers for you when performing calculations in later steps. Leave the Bicarbonate / Alkalinity value blank.

Our starting water profile and water amounts entered into Step 1 of EZWaterCalculator

Our starting water profile and water amounts entered into Step 1 of EZWaterCalculator

Steps 2 and 3 of EZWaterCalculator attempt to estimate your residual alkalinity (RA) and mash pH based on the grain used, the starting alkalinity of your water, and acids that you may add. We recommend skipping over these directly to Step 4. We don't care about the RA (more information below) and pH estimators are notoriously inaccurate due to the complexity of the calculations and the number of variables involved. Instead, we will later use a pH meter to take actual pH measurements and adjust if required. The mash is only one of many places where pH is important, so a pH meter is a handy tool to have.

In Steps 4a and 4b of EZWaterCalculator adjust the amounts of gypsum, calcium chloride, epsom salt, chalk, and baking soda on the two 'Mash Water Additions' lines (shown in yellow below) until the 'Mash + Sparge Water Profile' line in Step 5 (shown in red below) matches or is close to the desired mineral targets.

Adjusting salt amounts in EZWaterCalculator Steps 4a and 4b to hit our water profile targets in Step 5

Adjusting salt amounts in EZWaterCalculator Steps 4a and 4b to hit our water profile targets in Step 5

Some hints to making these adjustments:

- Most of the time we only add gypsum, calcium chloride, and epsom salt (the top 3 salts in EZWaterCalculator Step 4a which adjust mash pH down). We recommend starting with these three as follows: Increase epsom salt until the magnesium target is reached, then increase calcium chloride until the chloride target is reached, followed by increasing gypsum until the sulfate target is reached. If you need to increase only calcium, use chalk.

- Keeping sodium very low in most beers is the goal. Our water starts with a sodium level of 16 and for the most part we leave it there for most beers as lower amounts of sodium produces a cleaner flavour. If you are starting with a sodium level that is lower, feel free to add some baking Soda to raise the level slightly to match our recommended targets but do not feel it is required. If our starting sodium was at 5 or 10, we'd probably leave it at that. If your sodium is much higher than 30 however you may want to consider diluting with RO or distilled water.

- If you cannot hit the targets exactly, do not fret. The numbers are not absolutes. Keep in mind the original goal of the profile you are targeting. In this case the goal of this 'Balanced' profile is to "Hit minimums on Ca and Mg, keep the Cl:SO4 ratio low and equal". This means we prefer to reach 50 for calcium and 10 for magnesium, but a calcium at 60 or even 70 is fine, as is magnesium at 12 or 15. Keeping chloride and sulfate low and equal means that both at 50, 60, or even 80 is fine.

- Do not adjust the 'Sparge Water Additions' amounts directly. Instead, ensure that all six of the 'Adjusting Sparge Water?' checkboxes are checked and the spreadsheet will automatically calculate the 'Sparge Water Additions' amounts for you.

For our Blonde Ale we only need to add a bit of gypsum, calcium chloride, and epsom salt to hit our targets. In this case, we will be adding the following mash water additions (shown in yellow above) to the Mash / Lauter Tun together with the grain to help with the mash pH and flavour:

- 0.6 grams of gypsum

- 3.8 grams of calcium chloride

- 2.3 grams of epsom salt

The EZWaterCalculator spreadsheet has automatically calculated the sparge water additions (shown in green below) that will be added to the Boil Kettle to help mostly with flavour:

- 0.8 grams of gypsum

- 4.9 grams of calcium chloride

- 2.9 grams of epsom salt

EZWaterCalculator sparge water additions (added to the boil) are automatically calculated

EZWaterCalculator sparge water additions (added to the boil) are automatically calculated

What about alkalinity / residual alkalinity? I read that it was really important in brewing!

The short answer: Ignore it. While it's important, we don't deal with it directly when adjusting water to target specific flavour profiles.

The long answer: Alkalinity refers to how effectively water is able to resist a change in pH, in other words, how well it is able to neutralize or 'buffer' acids before the pH changes. The higher the alkalinity or 'buffering capacity' of the water, the more acids or salts we need to add to lower the pH in order to achieve a proper mash pH. Most city water has a pH of 7.0 or higher but the pH range we want for our mash and finished beer is considerably lower. Hard water (water full of minerals such as Ca and Mg) is highly alkaline.

In brewing, 'residual alkalinity' (RA) is actually what we care about (indirectly) as adding grain and salts will already lower the alkalinity and the buffering power we're left with is called the 'residual' alkalinity. Some books and articles will insist that RA is the most important water parameter when it comes to brewing. They will tell you to target a specific RA for the colour of beer you want to produce. The usual recommendation is that a low RA is best for lighter coloured beers, and higher is better for darker beers. The calculations are complicated and often calculators or nomographs (a type of fancy 2D diagram) are provided. Worrying about RA however is backwards, as RA is not something we target. What matters are the salts (for adjusting the flavour) and the mash pH (for proper starch to sugar conversion). If we do not achieve a proper mash pH after we've added our flavour salts, we simply add some acid to lower the mash pH into the proper range (more on this in a later step). The amount of acid required is usually minimal as we know the water cannot have been highly alkaline (hard), as otherwise we would have not have been able to hit our mineral targets in the first place as some of our starting water mineral levels would have been very high. Highly alkaline water is full of minerals and usually needs to be cut with RO or distilled water first in order to hit our mineral targets before we even begin to worry about mash pH.

What about the pH of the water? Isn't that important?

No. Ignore the pH of your starting water. How the water reacts to the various grains, acids, and salts we add is what matters. The goal is to achieve a mash pH that helps convert the starches to sugars. How easily your water's pH drops as you add the various grains, acids and so forth is a function of the residual alkalinity (see previous question), not the starting pH. In a later step we'll be adding acid to the mash if the pH is still too high after adding salts for flavour.

STEP 4: Measure salt additions

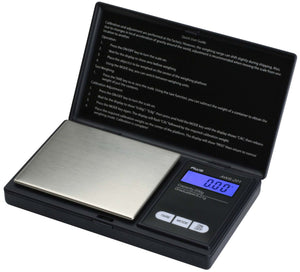

To measure the small amount of salt additions we use a jewelry scale with 0.01 gram resolution.

Most standard scales have at most a +/- 1 gram resolution, which is simply not accurate enough as an average 5 to 10 gallon home brew batch will usually only require a few grams of salts. You could easily end up doubling the amount of salts required without knowing it. A jewelry scale that provides us with the 0.01 gram resolution we need can weigh up to about 100-500 grams maximum which is more than enough for our needs. (100 grams is about the weight of a standard sized deck of playing cards).

We use small measuring spoons for scooping the various salts into small bowls on the jewelry scale, though just about any small spoon will do. We don't actually rely on the spoons themselves to measure our salt additions (that would not be very accurate).

As we measure out the salt additions we dump them into two small containers that have been labelled as 'mash' and 'boil'.

It's perfectly to fine to mix the salts. We typically measure out our salts the evening before the brew day. During the brew day the mash salts are added to the heated water in the Mash / Lauter Tun at the same time as the grain and mixed well with the mash paddle. The sparge salts are added to the Boil Kettle after we've come to a boil.

Measuring salt additions into two containers labelled 'mash' and 'boil'

Measuring salt additions into two containers labelled 'mash' and 'boil'

A jewelry scale is also perfect for measuring out hops and dry yeast that we purchase in bulk. While our jewelry scale cannot be calibrated, we use a calibration weight kit (10mg to 50 grams) to ensure that the scale remains accurate.

STEP 5: Brew day

During our brew day we add the various salts measured in the previous steps to the mash and to the boil, and make other water adjustments. For sake of completeness, below is a summary of the water adjustment steps we follow, some taken from our Brew Day Step by Step guide.

Removing chlorine / chloramine

Chlorine (or chloramine) is added to most public water supplies to kill disease-causing bacteria that the water or its transport pipes might contain. If left in, both can give beer a Band-Aid or plastic taste so it's best we get rid of it. We do this by adding potassium metabisulfite to our water at the start of our brew day.

Typical municipalities use up to ~3 ppm of chlorine or chloramine in their water (the US EPA drinking water quality standards limit the concentration to 4 ppm). Treat this water at a rate of 500mg of potassium metabisulfite per 20 gallons. We always start with 20 gallons of strike/sparge water in our Hot Liquor Tank and our municipality uses ~2 ppm of chloramine so a single 500mg dose is perfect for us. There's no harm in adding potassium metabisulfite if you're unsure if your city uses chlorine/chloramine.

We prefer the powder form of potassium metabisulfite and use a jewelry scale with 0.01 gram resolution to measure out 500mg. Campden tablets which are approximately 500mg are also available which can be either sodium or potassium metabisulfite. If possible, we recommend limiting the use of sodium in beer so use the potassium metabisulfite version if you go with tablet form (though the amount of sodium is arguably so miniscule to not make any difference).

We add this potassium metabisulfite directly to the Hot Liquor Tank after filling it with water at the start of the brew day. The chemical reaction is instantaneous, no waiting required.

Potassium metabisulfite loses efficacy over time so do not stock up. Most manufacturers recommend keeping containers tightly sealed and storing in cool dry conditions at room temperature. Shelf life is typically 12 months from the date of manufacturing.

Some brewers choose to use activated carbon based water filters to remove chlorine. Carbon based filters remove less chlorine as they become saturated, and the amount removed is directly related to the speed at which the water is passed through the filter making it difficult to know if the chlorine has been removed. This is why we use potassium metabisulfite instead. It's quick, dirt cheap, and works almost instantaneously. Activated carbon filters are also not overly effective at removing chloramine from water, requiring a more advanced reverse osmosis filtration system.

Brewers from years ago used to be able to simply leave water out overnight in their kettles to allow chlorine to evaporate, but today many municipalities have switched to using chloramine as it is more stable (doesn't break down or evaporate as easily). Leaving it out overnight will do next to nothing.

Measuring out potassium metabisulfite using a jewelry scale with 0.01 gram resolution

Measuring out potassium metabisulfite using a jewelry scale with 0.01 gram resolution

500mg (half a gram) of potassium metabisulfite really doesn't amount to much

500mg (half a gram) of potassium metabisulfite really doesn't amount to much

Adding mash salts & acids

When it's time to add the milled grain to the heated water in the Mash / Lauter Tun, add the mash salts at the same time and mix well with the mash paddle.

Gently mixing the grain and salts with the mash paddle

Gently mixing the grain and salts with the mash paddle

Remember that the mash salts we've added are primarily for flavour. Once well mixed and left for at least 10 minutes, we also need to confirm the mash pH. Most city water has a pH of 7.0 or higher but the pH range we want for our mash for optimal starch to sugar conversion is considerably lower. Fortunately the grains we mix with the water in the Mash / Lauter Tun are acidic (the darker the grain the more acidic it is) as are some of the mash salts we add. This helps to drive the pH down towards the proper range. We'll now check and add some extra acid if the pH isn't low enough.

Once the grains and mash salts are well mixed, take a pH reading by placing the probe tip of the pH meter directly in the mash. While the pH meter we use has automatic temperature compensation (ATC) up to a temperature slightly below typical mash temperature, we do not worry about cooling down a sample as the errors introduced are usually be minimal. The pH meter probe electrode will last longer if the sample is first cooled to room temperature, but ours (so far) has last 10 years when brewing once or twice a month, so we've never bothered cooling down a sample as it's much quicker. Feel free to cool a sample to room temperature if you prefer.

For optimal starch to sugar conversion we want the pH to be around 5.2 to 5.4, but only when measured in the mash temperature range of somewhere around 145-165F. pH changes with temperature, so if the sample has been cooled to room temperature, a pH of 5.4 to 5.6 is the target range instead of 5.2 to 5.4. Don't confuse the inclusion of automatic temperature compensation (ATC) in the pH meter to mean that the target range will always be 5.2 to 5.4 regardless of temperature, as that would be incorrect. ATC only compensates for the change in the electrical response of the pH meter probe with temperature. It does not compensate for the chemical/energy change in the water that naturally makes a hotter mash more acidic (lower pH). The pH target range will therefore always depend on the temperature of the sample: 5.2 to 5.4 when measured at mash temperature, or 5.4 to 5.6 when measured at room temperature. For more information see our Measuring pH guide.

Regardless of range, there is no 'one' correct mash pH as the various enzymes work best at different pH levels when converting the grain starches to sugars. While a wide range (from 4.5 to 5.6) is acceptable for mashing, most brewers will try and stay somewhere in the 5.2 to 5.4 range (when measured at mash temperature). A higher pH (more basic) produces a sweeter beer due to a less fermentable wort and more body. A lower pH (more acidic) produces a drier beer with thinner body due to a more fermentable wort. A lower pH also ensures better extraction efficiency, better hot break formation, lighter colour, and is less prone to form haze.

The most common problem brewers face with a light coloured beer such as our Blonde Ale is that the mash pH will be too high. If your pH is above the 5.2 to 5.4 range (when measured at mash temperature), add some 88% lactic acid half a millilitre (mL) at a time using a 1mL (1 cc) syringe, stir well and wait for at least 5-10 minutes, and re-measure until you get close to 5.2 (when measured at mash temperature). It usually only takes one or two millilitres at most for most beers in a batch this size if you were able to hit the proper mineral flavour profile in the previous steps.

Mash pH at 5.21 after adding mash salts and a bit of 88% lactic acid. Perfect!

Mash pH at 5.21 after adding mash salts and a bit of 88% lactic acid. Perfect!

Some people chose to use 10% phosphoric acid instead of 88% lactic acid as they say it cannot be tasted as easily as lactic acid. This is not an issue as lactic acid in the quantities we use (0.1-0.2 mL per gallon) simply cannot be tasted even in the lightest of beers. You need at least 10 times the amount before it becomes noticeable. Some also say that phosphoric acid will precipitate calcium out solution which could throw brewing salt additions out of whack but they are only very miniscule/irrelevant amounts that will not affect the final beer. We choose to use 88% lactic acid as it works well for us. Feel free however to use whatever acid you like. Some other acids commonly used in brewing also include sulphuric and citric acid.

If you prefer to brew to Reinheitsgebot (German Beer Purity Law) standards where acids cannot be used, you may replace a small amount of the base malt with acidulated malt which contains a small proportion (usually 1-2% by weight) of lactic acid. How much is done mostly through trial and error as you brew repeat batches, as adding more will throw off your starting gravity since adding grain adds sugar. We find it simpler to add acid separately.

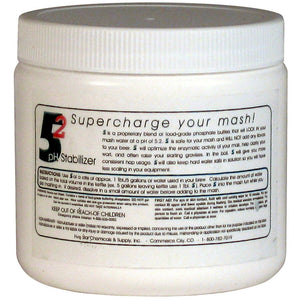

What about Five Star 5.2 pH Stabilizer? Can I use that to lock my mash pH at exactly 5.2?

In our experience the product does not work as advertised. We recommend sticking with acid additions and measuring with a pH meter. For more information see the tests we performed on our 5.2 pH Stabilizer page.

Acidifying sparge water

Before we sparge (rinse the sugars from the grain using the sparge water in the Hot Liquor Tank) we want to ensure that the pH of the water isn't too high. Too high of a pH can extract excess tannins from the grain husks. While all beer will have some tannins, with most beers (including this one) we want to try and minimize the amount. Tannins have a tongue-drying astringent taste like over steeped tea or strong red wine.

We want the sparge water pH to be below 6.0 (when measured at mash temperature), preferably in the 5.6 to 5.8 range. Before sparging take a pH reading by placing the probe tip of the pH meter in the Hot Liquor Tank. If the water is well above the temperature your pH meter is able to compensate for you may want to extract a sample and wait for it to cool slightly first. To lower the pH, add some 88% lactic acid half a millilitres (mL) at a time using a 1mL (1 cc) syringe, wait a minute for the acid to recirculate and mix through the pump, and re-measure. It usually only takes us one or two millilitres at most in 10-13 gallons of sparge water to get down into the 5.6 to 5.8 range. All water is different however. Once you know how your water reacts, you'll be able to adjust it without having to measure the pH every time.

We usually acidify the sparge water while the mash is proceeding.

Adding boil salts & acids

After the wort has come to a boil in Boil Kettle and the foam (called 'hot break') has subsided, add the sparge salts to the boil.

If desired, after allowing a few minutes for the salts to dissolve and mix in the boil, take a sample and measure the wort pH using the pH meter. It should be around 5.0 to 5.5 (measured at mash temperature). If it is too high you may want to consider adding some 88% lactic acid to get it down into this range. If the mash pH was ok then the wort pH is most likely fine too unless the water you use is very hard. A pH in the lower end of this range helps produce a good protein break during the boil which in turn helps with beer clarity and long term stability. A lower pH also minimizes colour formation (important if the goal is to maintain a lighter coloured beer) and helps ensure a less harsh hop bitterness (even though hop utilization is actually increased at higher pH).

Measuring the wort pH in the Boil Kettle before boiling

Measuring the wort pH in the Boil Kettle before boiling

That's it! We hope you've found this water adjustment guide easy to use and that it helps you step your brewing up a notch.

See our Brew Day Step by Step guide for further details on how these water adjustments are incorporated in our typical brew day.

Cheers!

Pictures / Videos

Interested in seeing what we're brewing right now? Follow us on Instagram for pictures and videos of our brewing activities as they happen.